Electroplating lines

We supply technological equipment for the following processes:

Galvanizing plants for electrodeposition & electroplating

-

zinc plating incl. post-treatment (chromating, chrom-free passivation and sealing)

-

zinc alloy plating: zinc-nickel, zinc-iron etc. including post-treatment

-

chrome VI-free application

-

zinc multi-plate coatings

-

plastic- and ABS-Electroplating

-

copper plating / deposition

-

chromium plating (decorative, hard chrome plating)

-

nickel plating (dull, pearlescent, satin finish)

-

tin plating and Sn-Pb alloys

-

precious metal plating: gold & gold alloy platting; silver plating etc.

-

aluminium anodising; chemical oxidation of aluminium (decorative, chrome, hard)

-

electrolytic polishing

Chemical surface treatment

-

phosphating: manganese phosphating, thick-coated phosphate

-

metal colouring (metal blackening etc.)

-

passivation, preservation

-

chemical metal plating (electroless nickel, copper and other metals)

Electrochemical and chemical plating of printed circuits (PCB)

-

electroplating of copper, tin etc.

-

chemical plating of gold, tin, nickel etc.

-

chemical surface treatment

We deliver:

-

automatic lines

- highly productive equipment with low demands on human service and consistent high quality of the final product

- the transport system of the line moves according to the program automatically -

manually operated lines with mechanization and with different levels of automation

- semi-automatic (operations such as filling the baths, controlling the composition of the bath are controlled automatically)

- suitable for low-capacity devices with lower demands on the final quality

- the transport system of the line moves exclusively according to the operator's instructions -

special plating equipment

-

visualization and free programs

Our galvanizing line for Tesgal-Holzapfel in Slovakia, read more about it:

Rack lines

Rack lines are suitable for larger goods, which can be placed on rack or in basket.

Barrel lines

Surface treatment lines for mass processable parts in barrels.

-

Single or twin barrels

-

Blowing and rinsing system to save chemicals and rinse water

Centrifuge baskets

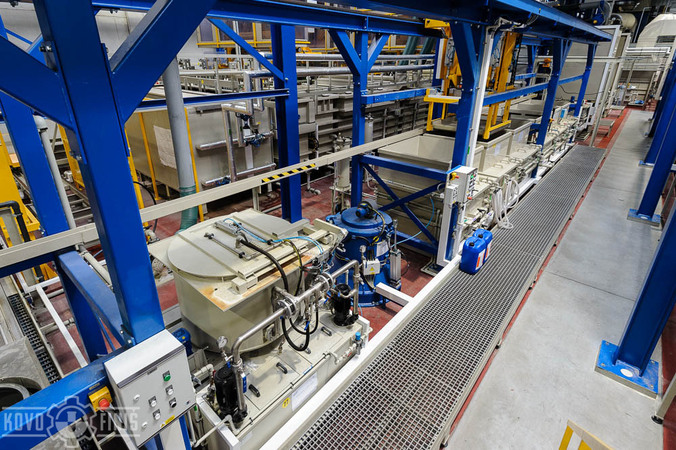

Centrifuge baskets are suitable for bulk treated small-sized goods. Main advantages are very gentle prats processing, minimal bath out take and high quality of final surface. For transport we use specialy designed manipulators with tilting vertical axis. Manipulator is equipped with motoric drive for basket rotation in both directions.

Centrifugal baskets are also suitable for treatments that follow the surface treatment itself, such as passivation or sealing. It is not necessary to transfer the goods to another basket, thus avoiding abrasion of the goods. Wet loading or unloading can be used for loading or unloading baskets. The goods are transferred to a basket immersed in water, thus causing minimal abrasion.

Loading and unloading of centrifugal baskets can be automatic or manual. Lines using centrifugal baskets are usually equipped with cleaning stations for cleaning the baskets. This ensures a long service life of the baskets themselves and a consistent quality of the final products.

Carousel lines

Carousel lines are very productive plants which are suitable for large series of similar size products.

Carousel lines operates in constant steps. Lines can be equipped with barrels or racks.

Transport systems

We supply a range of different conveyor manipulators for surface treatment lines to transport racks, barrels and baskets in the lines.

-

Overhead transport systems

- the most common transport system solution

- the track of the transport system is located below the hall ceiling,

- different range in terms of size, weight of goods and line capacity -

Gantry transport systems

- the conveyor track is installed just above the line

- the advantage of this solution is less space requirement in the vertical direction -

Side transport systems

- the simplest variant of the transport system

- the advantage of this solution is a very low space requirement of the entire conveyor

- however, the conveyor system is limited by the maximum load capacity of the whole system -

3D Cartesian conveyor – 3-axis movement

- the most advanced type of conveyor system

- in addition to the standard forward, backward, up and down movements, the conveyor can also move laterally

- goods can move between different rows of the line on a single conveyor

- one conveyor can serve several rows of the line

- this solution can reduce the number of rinsing positions in the entire surface treatment line

- suitable for lines that are divided into several rows due to the layout of the hall -

Tilting and rotation for centrifugal baskets

- this solution seeks to remove as much of the bath left on the goods as possible

- tilting helps to remove the bath from the cavities of the goods -

Trolleys for transfer between rows of lines

- used to transport goods between conveyors

These conveyors can be equipped with additional equipment

-

Drip pan

- helps to minimise the transfer of baths between tanks when transporting goods over the tanks - saving chemistry, reducing the waste water produced

- prevents baths from dripping onto the line equipment itself - extends the line service life

- all captured droplets are discharged to the WWTP -

Exhausted cabin

- helps to maintain a safe area around the line

- harmful gases generated, when opening the lids of the tanks and transferring the goods between operations, are exhausted from the surroundings of the goods

- protects the steel parts of the equipment from corrosion

- protects the health of line operators -

Spray system

- inter-operational cleaning and other operations can take place directly on the conveyor without the need to immerse the goods in the bath

- saving operating time and line size demands -

Blowing and flushing

- goods are flushed and blown directly on the conveyor

- prevents the transfer of baths between operations - saving chemistry and rinse water, reducing the waste water produced

- quality of the entire surface treatment process, as droplets are prevented from adhering to the goods

Loading and unloading section

Inlet and outlet sections of galvanic lines are designed depending on the type of line.

Rack lines

The rack lines are equipped with stands for loading and unloading of racks. The loading and unloading can take place outside the line itself. This saves space in the surface treatment hall itself. A possible solution is also a two-storey system, where the loading and unloading of goods takes place on the ground floor and the line itself is located on the first floor. The entire facility fits into the built-up area of a smaller multi-storey building while maintaining a more than comfortable amount of space for the necessary logistics of the goods.

The goods are then transported with the entire rack by a hand truck or by means of a lift to the line. The racks can also be transported using roller tracks. In automatic lines, the loading section is often the only place where human labour is required.

Loading and unloading can be done at several stations at the same time, so that in high-performance lines there is no bottleneck at the inlet and uninterrupted operation of the line is ensured.

Loading and unloading outside the line itself improves the working conditions of the workers in this section. It also increases safety in the workplace, as these workers do not come into contact with any chemicals and work with a few moving parts on the line only.

Barrel lines

The inlet and outlet sections of barrel lines can be designed with either an automatic or manual system.

Automated loading and unloading of barrels include:

- Pallet and box tippers

- Vibrating feeders

- Belt conveyors

- Scales

When the inlet section of the line is automated, a pallet or a suitable box is fed into the line. This is tipped into the hopper and discharged by means of a tipper. From there, the goods are transferred to the barrels of the line using vibrating feeder and belt conveyors. A precisely weighed quantity is always dispensed into each barrel to match the specified recipe for the goods and to optimise the use of the entire barrel.

The automated solution for loading and unloading the barrels significantly improves the efficiency of the line and significantly reduces the number of workers.

Surface treatment lines are usually equipped with rack and barrel storage to ensure continuous operation of the line.

Effective, efficient and ecological solutions

We deliver our surface treatment lines with equipment which makes the process more effective and increases its quality.

- Degreasing, cleaning and rinsing with ultrasound

- Bath ejector agitation

- Horizontal, vertical and two-dimensional rack movement,

- Rack percussion and vibration

- Diaphragm frames

- Selective bath cleaning

- Rinse water saving systems with controlled water flow

- Rinse water circulation through ion exchangers

- Tank and dryer covers

- they prevent the leakage of harmful vapors created in the bath into the area of the surface treatment hall

- the resulting vapors are sucked into absorbers with the help of ventilation

- in the area of the line there is a breathable harmless atmosphere - without the need to wear protective breathing equipment

- capture of aggressive vapors extends the life of the entire device - Heat recuperation from waste air

We use numerous recovery and recycling applications in order to reduce environmental pollution and consumption of chemicals.

Used techniques:

- Oil separation from degreasing baths – separators or microfiltration

- Sludge removal systems

- Bath regeneration with

- Crystallization

- Ion exchanging

- Retardation - Bath recycling with the use of evaporators

- Atmospheric

- Vacuum - Precious metal extraction

- Waste air cleaning with scrubbers

Technological accessories

We supply technological accessories for surface treatment lines, which ensure the operation of the line and facilitate maintenance and operation.

-

Bath preparation units

- are used to prepare the correct composition of the bath outside the surface treatment line itself, prepared bath is better mixed and pre-prepared solution is dosed into the line -

Reserve tanks

- reserve tanks are used in case of maintenance or accident to pump the baths or chemistry for temporary storage when the primary tank is out of service

- reserve tanks significantly reduce the amount of waste produced by the plant -

Online bath analysers

- allow monitoring of the current bath composition and, in conjunction with an automatic dosing system, actively manage the bath composition -

Automatic chemical dosing

- allow automatic dosing of chemicals without the need for human operator intervention -

De-hydrogen furnaces

- used for de-hydrogen and hardening of goods using high temperature -

DI-station

- for the production of DI-water (DI-water storage tanks, reverse osmosis, ion exchange stations) -

Supply air systems

- provides exchange of exhausted air from the area around the surface treatment line

Surface pretreatment

Chemical and electrochemical surface pre-treatment

Surface pre-treatment prior to polishing, cold, forming, electroplating, galvanizing or paint coating as:

- separate equipment

- or as a part of the surface pre-treatment lines

We provide processes plants for:

- cleaning & degreasing (chemical, electrolytic, ultrasonic)

- pickling of steel, non-ferrous metal, light metal and their alloys

- phosphating (zinc and multi-cationic, iron phosphating)

- aluminium pre-treatment (chromate treatment, non-chromate conversion coatings)

- stripping of paint, metal and alloy coatings

We deliver:

- complete dipping lines and PT-Tanks

- part of automatic surface treatment lines

- pretreatment by spraying or/and dipping

Industrial cleaning machines

We supply:

- machines for industrial cleaning and degreasing ev. including phosphating or passivation

- cleaning machines by means of spraying, dipping and ultrasonic

- designed as one box machines or multi-stage machines

We deliver:

- continuous cleaning machines

- chamber batch cleaning machines

- rotation washing machines

- spraying chambers

- immersion table machines