Cooperation in industrial production

Wide possibilities are at cooperation in the mechanical production especially in section of stainless and plastic materials. Production base facilities and technical background enables us to deliver complex services.

Our company is a holder of ISO 9001:2008 and ISO 14001:2004 certificates.

Contact: Tomáš Janda

+420 728 547 166

tomas.janda@kovofinis.cz

Sheet material indexing

Shearing

- table shears max. material thickness 10 mm, shear length 3 m

Water jet cutting

- metallic and non-metallic materials max. thickness 150 mm, sheet size max. 3000 x 1500 mm

Flame cutting

- carbon steel, max. thickness 200 mm, max. sheet size 4000 x 2000 mm

Plasma cutting

- stainless steel, max. thickness 50 mm, max. sheet size 4000 x 2000 mm

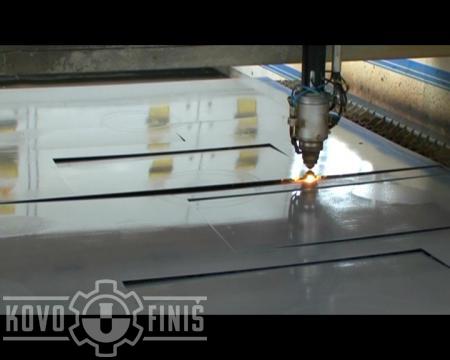

Laser cutting

- carbon steel, max. thickness 20 mm

- stainless steel, max. thickness 15 mm, max. sheet size 4000 x 2000 mm

CNC gantry-type milling machines

- form cutting of plastic and wood-based boards, max. thickness 15 mm, max. sheet size 3600 x 1800 mm

Dimensioning saws

- plastic and wood-based boards, max. sheet size 4000 x 2000 mm, max. thickness 15 mm

Cutting of bars

Band saws

- cutting of metallic and non-metallic bars and profiles up to max. cross section 420 x 420 mm

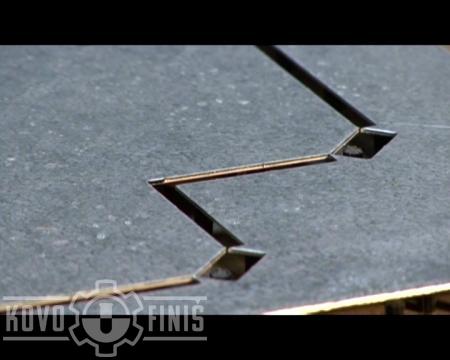

Forming

Metal sheet forming

- press brake max. bending length 6000 mm, max. thickness of bended material 12 mm – depending on the bending length, computer-controlled process

Metal sheet bending

- max. sheet thickness 14 mm, max. width 2500 mm

Profile bending

- 100/16mm from Ø 500 mm, 35/35 mm from Ø 600 mm

Tube bending

- jig equipment up to tube Ø 108 mm

Welding, soldering

Welding and brazing of metal materials

- welding with – flame, coated electrode, MIG/MAG, TIG

- welded materials – carbon steels including high-grade steel, stainless steel including duplex and super-duplex steel, copper and its alloys, aluminium and its alloys

- brazing with – tin, brass and silver solder

- all joints including preparation are made according to approved procedures (WPS, WPQR)

- all welding work is carried out only by qualified welders and the entire welding process is managed by our own international welding technologist and international welding engineer

- high quality of the welding process control is verified by the standard ČSN EN ISO 3834-2:2006

Welding and bonding of plastics

- welding method: poly-fusion – tubular materials up to Ø 200 mm, sheets up to 30 mm thickness and 3000 mm joint length

- hot air welding with accessory material - limited only by handling dimensions

- bonding - limited only by handling dimensions

Assembly

- we carry out assembly of complex engineering equipment and technologies including assembly, wiring, commissioning, issuing of reports and inspection reports (electrical, hydraulic, pressure air, cooling and others)

- we have trained our own inspection technicians and we also cooperate with external companies

Machining

Turning

- CNC lathes from Ø 50 mm up to Ø 450 mm and workpiece length of 4500 mm

- conventional lathe with max. Ø 320 mm and workpiece length of 6000 mm

- conventional lathe with max. Ø 950 mm and workpiece length of 4000 mm

- range of conventional lathes with different specification

Drilling, boring, milling

- CNC horizontal boring and milling machine series 130, 160 - max. workpiece size is 6000 x 2200 x 1200 mm

- CNC milling machines – max. workpiece (table) size is 800 x 600 x 500 mm

- conventional horizontal boring machines series 90, 100

- conventional milling machines, drilling machines

- hobbing machine for external teeth – max Ø 600 mm, max. module 6

- slotting of internal grooves for slotting machine

Grinding machines

- vertical spindle surface grinding machine – clamping area 300 mm x 1000 mm

- surface grinding machine BPH 20 - clamping area 200 mm x 630 mm, stroke 350 mm

- round grinding machine BHU 40 – ground Ø 400 mm, length 1500 mm

- round grinding machine BUT 63/4000 – ground Ø 850 mm, length 4000 mm

Dynamic balancing

- weight of the balanced part up to 1000 kg, max. Ø 1000 mm, length 4000 mm

Surface treatment

Plating plant

- zinc, nickel, chrome plating – see link

- maximum dimension of parts:

- nickel, zinc plating: 1000 mm x 600 mm x 100 mm

- chrome plating: 500 mm x 400 mm x 100 mm

- electroless nickel plating: 500 mm x 300 mm x 100 mm

Wet painting

- air and air-less (high pressure) application of solvent coatings including system surface finish in two booths of 15000 x 5000 mm each

Powder coating plant

- powder coating in line or in a separate booth, max. size: 600 x 1100 x 900 mm – see link

Blasting

- chamber blasting machine max. size 2200 x 2200 mm, blasting with steel granulate

- continuous blasting machine for bar material, max. cross-section 400 x 400 mm, blasting with steel granulate

Stainless steel etching

- dipping, tank size 3500 x 3000 x 1000 mm

- spraying