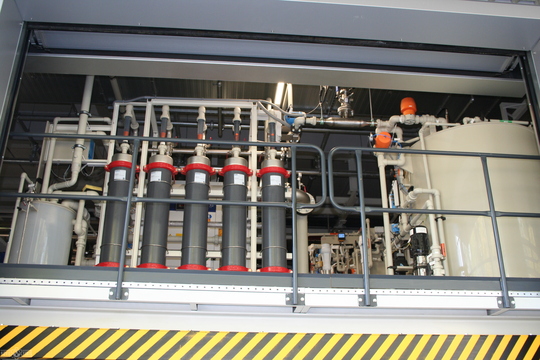

Membrane processes

Membrane processes are used for separation of substances with the use of semi-permeable membranes. The process is based upon ability of substances to go through pores of membranes to the other side.

The inlet solution is fed to one side of the membrane and due to the pressure differential induced on both sides of the membrane, the inlet solution is forced to pass to the other side of the membrane. Only substances with a smaller diameter than the diameter of the membrane pores pass through the membrane. Particles with larger diameters are retained on the membrane.

Membrane processes have two outputs. Permeate is a solution containing substances that pass through the membrane. Retentate is a solution containing substances that are retained on the membrane. The usability of permeate and retentate depends on the specific application of the processes.

Membrane processes include microfiltration, ultrafiltration, nanofiltration and reverse osmosis. Each type differs in the type of semi-permeable membrane, membrane pore size and pressure under which the process runs. Separation of smaller particles requires smaller diameter of membrane pores and higher pressure differential for particles to go through membrane.

The best results of membrane separation are achieved through a series of series-connected devices in the order of microfiltration, ultrafiltration, nanofiltration and reverse osmosis. Substances are separated from the largest particle diameter to the smallest. This achieves the longest possible life of the device, since large diameter particles are trapped in the first phases on coarse membranes and do not foul finer membranes in subsequent separation steps. The membranes are cleaned by demineralized water backwash.

Usability:

-

surface treatment

-

pharmaceutical industry

-

food industry

-

textile and paper industry

-

electrotechnical industry

-

power plants

-

waste water treatment

Advantages:

-

substance separation effectivity up to 90%

-

decreased chemical consuption

-

ability to remove microorganisms

-

low energy consumption

-

automatic and continuous flow

Microfiltration - MF

separation of substances from 10 to 0,1 μm in diameter

- separation of undisolved substances and bacteria

- oil emulsion thickening

- pretreatment before ultrafiltration and reverse osmosis

Ultrafiltration - UF

separation of substances from 0,1 to 0,01 μm in diameter

- separation of viruses, colloidal substances, macromolecules and proteins

- oil emulsion processing

- paint recyclation from rinse water during electrophoresis

- pretreatment before reverse osmosis

Nanofiltration - NF

separation of substances from 0,01 to 0,001 μm in diameter

- water softening

- separation of mono- and di- saccharides

- textile colorant separation

- pretreatment before reverse osmosis

Reverse osmosis - RO

separation of substances from 0,001 to 0,0001 μm in diameter

- desalination of sea and brackish water

- ultraclean water production

- demineralized water production

- waste water and production water treatment

- high-pressure boiler water production