Control and visualization systems - Automation

Control and visualization systems - Automation

We supply complete software control of the entire technological process to our plants. Automatic control of the line/plant operation reduces the amount of human labour required, increases plant efficiency and ensures consistent quality results. Despite the initial higher investment, automatic plant control is economically more advantageous than manual control due to higher productivity, consistent process quality and lower operator requirements.

The software solution is the result of development by our own programming team and is continuously being improved. We are therefore not dependent on an external control system supplier. For each customer we design an order-made control system to meet their requirements and ideas. We always run our systems on the latest version of the SIEMENS Simatic platform, which allows almost unlimited flexibility of the solution.

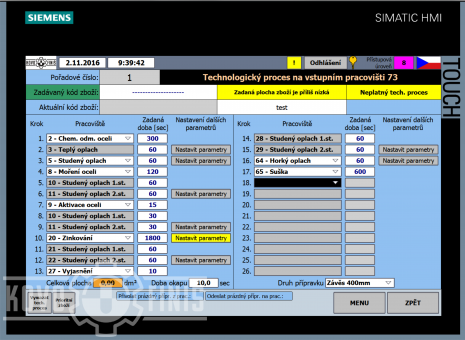

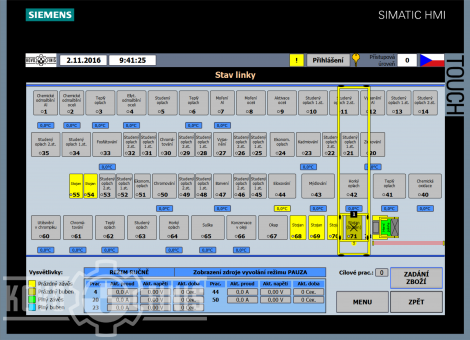

Thanks to our system, production can be planned efficiently. The system efficiently plans the use of production line capacity. The system performs simulations of future operations so that it can accurately plan individual line operations and schedule the passage of goods through the line to achieve optimum line utilization while adhering to all specified recipes. The system clearly displays all this information to the line operator on a touch panel at the line or on a PC. The operator thus knows exactly when and in what order the goods will be returned to him before the operation starts. The line operator can therefore focus primarily on the inlet and outlet sections of the line and leave the rest to our system, which takes care of the rest.

The system allows freely programmable recipes, as well as a custom recipe for each rack in the line. There can be multiple items in the line at one time, each with its own recipe. The automation system itself resolves any collisions and plans the optimal passage of goods through the line.

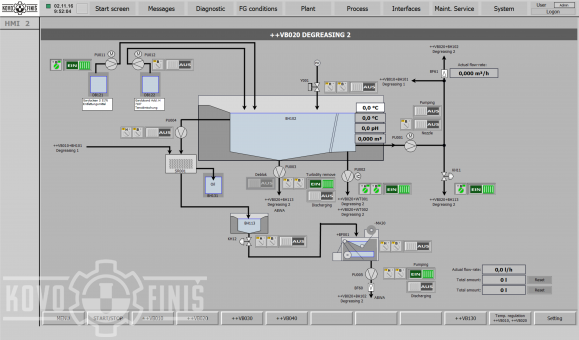

Our systems communicate with each other! The system controlling the surface treatment line communicates with the system controlling the WWTP and vice versa. This prevents production deficit and overcrowding at individual nodes. For example, the line knows exactly when it can discharge waste water to the WWTP. It also knows, for example, exactly how much DI-water it has ready in the treatment plant and can plan its production in advance so that there is never a shortage.

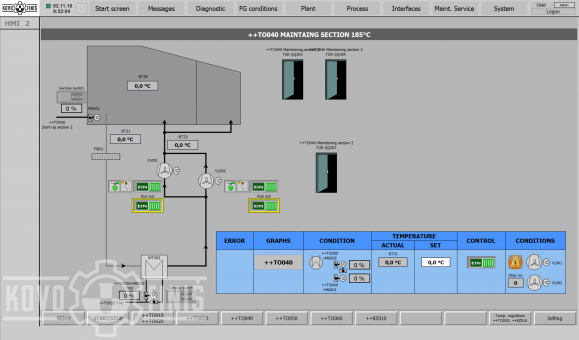

Automatic regulation of:

- temperature

- current

- levels

- dosing

- movements and lifts etc.

Visualization of technology process

- on PC monitor or touch screen near the device or remote workplace:

- display of equipment operation

- fault warning

- data recording and storage, parameters statement and print

- actual parameters statement (print) as well as the reverse statement for the queued protocol

- different access level - access password

Archiving:

- goods archive: parameters for each charge (goods code, date and real time, operating times, temperatures)

- event archive: date and time of line start, fault conditions, pause occurrence, dosing of additives

- performance archive: number of charges per time period